Wednesday 29 December 2010

Temperature Conundrum

Thursday 23 December 2010

Converting a "Burco" style boiler to a Hot Liquor Tank

As I may have bored you about recently, I picked up a 25L tea urn type boiler a couple of weeks ago for next to nothing (did I tell you I only paid a fiver) and today I set about converting it into a Hot Liquor Tank (HLT).

First of all, why would you want a separate HLT and Copper? Many brewers quite happily manage without as did I until I realised how much more convenient it was to have the copper bringing the wort to the boil at the same time as I was finishing off the sparging.

So, without further ado, take your boiler, descale and clean it if it is a second hand like mine was then remove the tap. Actually, if you don't want to remove the tap it wil stiff function perfectly well but I want to fly sparge, again to save hassle and time so I've made the conversion.

You will need

- a length of 15mm copper pipe

- a 15mm compression fit ball valve

- two 15mm compression fit end caps

- a 15mm tank connector

- 90 degree elbow

- 15mm speed fit t-piece

- PTFE tape

Tools

- 2 x adjustable wrenches

- pipe cutter

- scissors

- drill & drill bits

You could use a compression fitting T piece but, as I need to remove and attach the sparge arm frequently, I've opted for the speed fit option.

First thing to do is to place the tank connector into the void left by the removal of the old tap. Try to get it as central as possible to avoid potential leakage.

Once the tank connector is in place, assemble the ball valve and 90 degree angle with the three bits of pipe required to connect them together. While putting these together get then roughly in position and trim the pipe afterwards if required.

Once I'm happy with the alignment, I dismantle and reapply piece by piece with PTFE tape. It is important to apply the tape in the opposite direction to the travel of the nut to ensure a good seal. The finished assembly should look like this.

When you've completed that, it is time to test it for watertightness under pressure. For this it is important to fill the vessel as full as you can and then put it on to boil. If you see any leaks - note from where, drain down and reseat where necessary.

While the water is coming to temperature, you can start on the sparge arm. You don't have to use a T-piece, you could just as easily use another 90 degree bend but I've chosen this method. All I did here is cut the remaining pipe in half and fit the endcaps to the speedfit tee. To end up with this.

Tomorrow I shall be drilling in on each side of the tubing (i.e. 90 degrees each side of the upright part of the tee) so the water will exit both sides of the sparge arm. Hopefully I will be able to test this sooner rather than later, on a brew between Christmas and the New Year.

Monday 20 December 2010

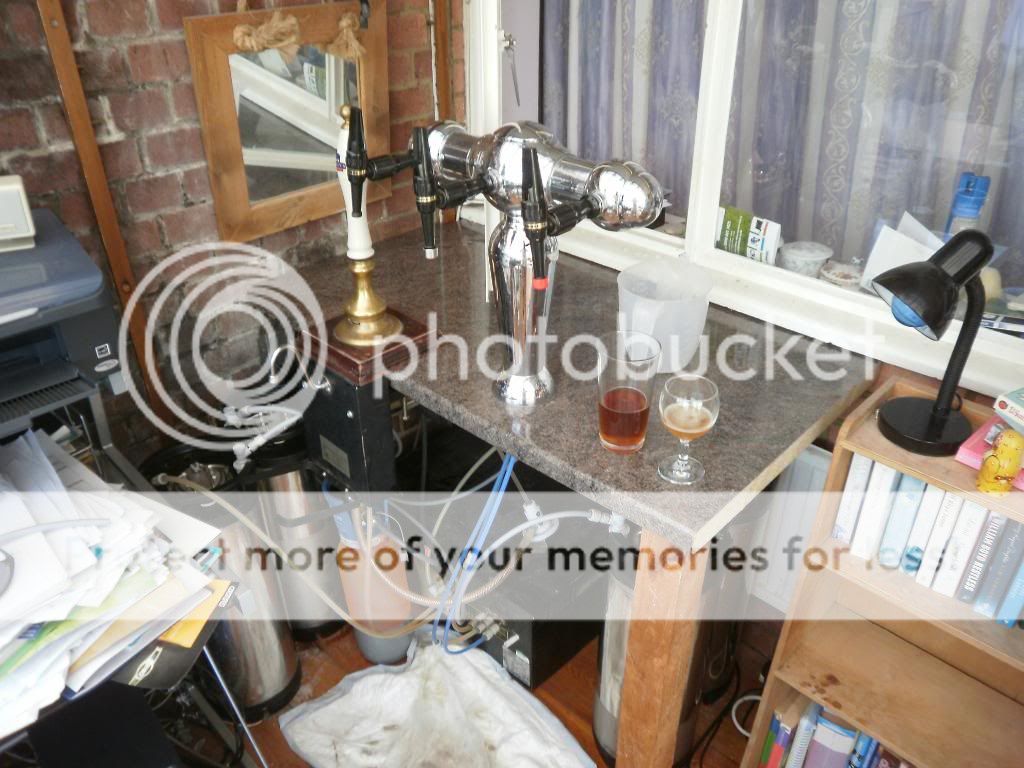

What's On the Bar this Christmas

I filled the Cornie with some Irish Extra Stout this evening, and realised that I've now got three of them on at once which must rank as pretty bad planning.

Christmas Brewery Modifications

Delighted to report that I've been able to source a cheap hot liquor tank (HLT) for the brewery which should speed up some of the processes and enable me to start fly sparging.